The effective use of 3D documentation:

viin carries decades of expertise in the management and execution of digital documentation projects and is among the German pioneers in employing laser scanning technologies to meet the particular needs of the industrial plant sector. We bring together the latest hardware, exceptional on-site performance and optimized post-processing techniques in a way that ensures benchmark quality outputs.

By applying laser scanning techniques, significant benefits are drawn for engineering tasks: construction, pipeline surveys, area management of equipment, deformation analysis, clash detection as well as documentation purposes. 3D laser scanning is used for plant revamps, retrofits, verifications and relocation projects.

Combining Plantview, our software platform together with our hardware solutions for rapid data capture we are able to offer services that range from asset documentation for navigational purposes to a whole new take on the way project visualization is made in the plant industry.

HDR panorama imagery ranging from 50 megapixels up to several gigapixels can be utilized as a cost-effective documentation solution during all phases of a project. Engineers can quickly share information based on what they see. The surroundings can be re-enacted with exceptionally high detail, bringing in a whole new level of virtual access to the plant.

During design reviews, virtual tours that combine HDR panorama photography, 3D point cloud data and 3D models can be used for measuring distances and sizes in the virtual facility in order to provide a detailed and actionable monitoring of the prospective fit of new equipment.

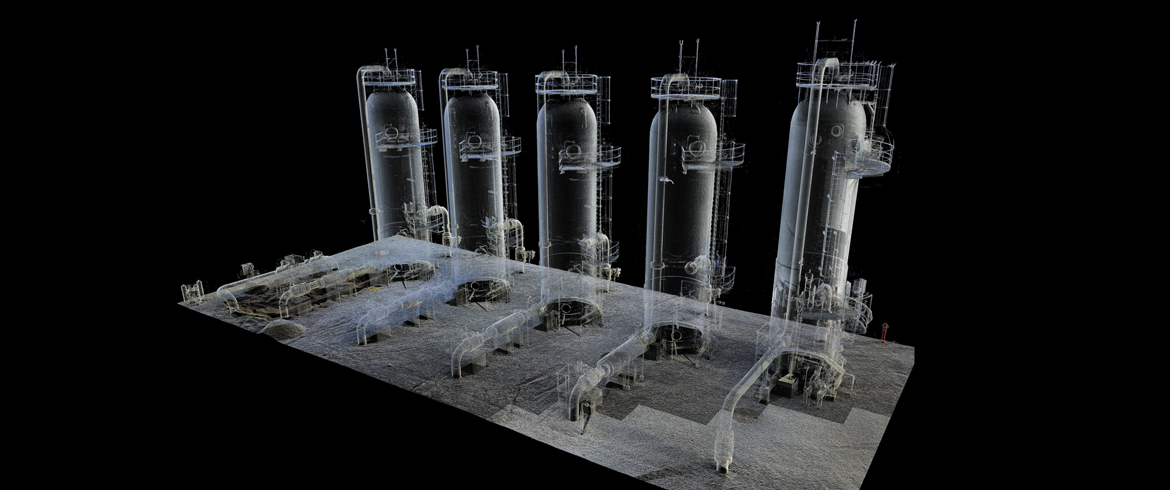

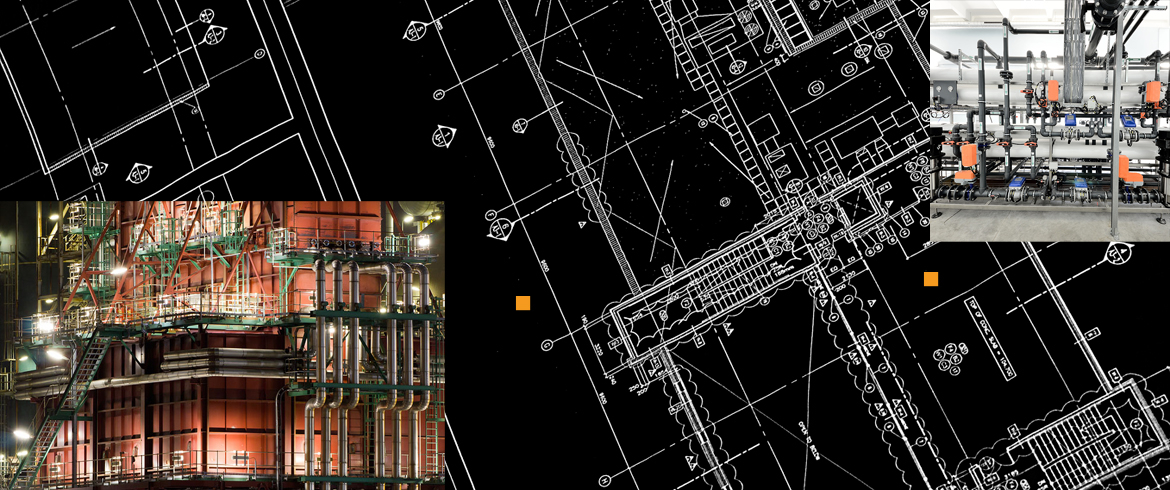

3D Laser Scanning is the fastest and most efficient way to produce AS-Built documentation. Using existing point cloud data, by prioritizing accuracy, completion time and cost efficiency, we can produce high quality 3D models at any level of detail and intelligence, from piping and layout plans to isometrics, MTO/BOM and equipment volume occupation.

We deliver models for all major design platforms like PDS, PDMS, Smartplant 3D, Autocad, Microstation and we can flexibly adjust our offerings depending on the scope of the project.

Modern reverse engineering and 3D visualization methods can examine and document the dimensional, volumetric and geometrical deviations between as designed and as built for equipment, pipes or steel structures.

Using extensive documenting techniques such as 3D deviation analysis, planar deviation analysis, section comparison or deformation analysis, we can produce insightful documentation to support the decision making process on whether or not corrective interventions need to be made.

As-built 3D data can be employed for a series of simulation applications reducing project execution risks, better visualization and support for off-site prefabrication thus leaving space for more accurate project planning. 3D walkthroughs that incorporate both "As-Built" point cloud data and 3D models of future structures, during design phases, can reveal interferences and incompatibilities. Design reviews can in this way be based on real-world dimensional data.

What we assist in, is ascertaining that any possible interference in your configuration can be foreseen before it becomes an issue and most of all, before it becomes an unexpected cost.

Accurate isometric drawings are of strategic importance both for asset management in the long term as it is for the actual day to day operations. 3D Laserscanning data along with specialized software tools, can be used for the extraction of As-Built and intelligent isometric drawings.